The primary pollutants generated from industrial operations are oil and solids. Oily waste is generated from any number of sources around industrial facilities. Other than process waste, pollutants are generated by support operations such as equipment steam cleaning, maintenance wash down, and eyen natural occurrences such as rain water runoff.

“Specific Pollutant Limitations” and the “National Categorical Standards” limit the amount of “dispersed” and floatable oil and grease allowed to be discharged to public owned treatment works. Additionally, most sanitation districts limit the amount of solids that can be discharged.

The most consistent maintenance and operation-free method to remove these pollutants from waste water is through the use of gravity separation. Various methods of separation and applications to fit specific site conditions are illustrated in the Industrial Waste section of this website.

Criteria for sizing these systems varies from district to district.

Excavation Preparation

Excavation must be accessible for our delivery equipment. Bottom of excavation must be dry, level and have a base of gravel or other suitable material compacted to handle anticipated loads.

| Product Name | Part Number | Drawing(PDF) / Specification(PDF) |

||

|---|---|---|---|---|

|

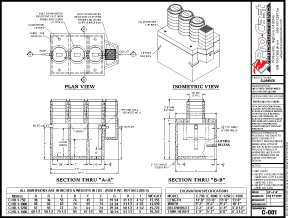

750 THRU 1500 GALLONS WITH THREE COMPARTMENTS DESIGN LOAD: H-20 LOADING |

C-001 | Drawing Spec Sheet |

|

|

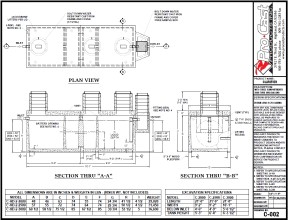

2000 THRU 3000 GALLONS WITH THREE COMPARTMENTS DESIGN LOAD: H-20 LOADING |

C-002 | Drawing Spec Sheet |

|

|

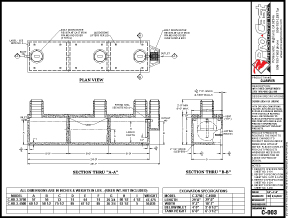

3750 THRU 4500 GALLONS WITH THREE COMPARTMENTS DESIGN LOAD: H-20 LOADING |

C-003 | Drawing Spec Sheet |

|

|

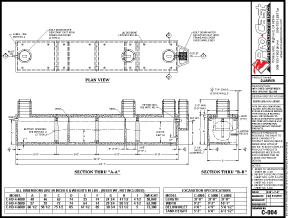

4000 THRU 6000 GALLONS WITH THREE COMPARTMENTS DESIGN LOAD: H-20 LOADING |

C-004 | Drawing Spec Sheet |

|

|

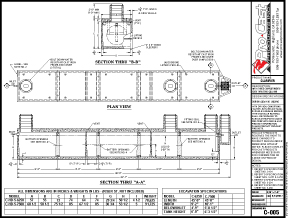

6250 THRU 7500 GALLONS WITH THREE COMPARTMENTS DESIGN LOAD: H-20 LOADING |

C-005 | Drawing Spec Sheet |

|