Pro-Cast Products, Inc began as a manufacturer of precast tanks. For years, Pro-Cast has been a leading provider of concrete, precast septic, clarifiers, grease interceptors, sand traps and holding tanks to Southern California.

When you think of precast. Think of Pro-Cast.

909-793-7602 • Highland, California

by pete

Pro-Cast Products, Inc began as a manufacturer of precast tanks. For years, Pro-Cast has been a leading provider of concrete, precast septic, clarifiers, grease interceptors, sand traps and holding tanks to Southern California.

The same question but with a other main man this how to catch your boyfriend cheating or even just say without fear how to catch your wife cheating can also be done.

“Turning PRO-CAST PRODUCTS into a one stop shop for Precast Products in Southern California….”

Click here to view the magazine article

Precast Solutions Magazine Winter 2005 | Protecting Our Power

Post-9/11 concerns brought precast concrete into the national security spotlight.

by Jason

Breakwaters are structures constructed on coasts as part of coastal defense or to protect an anchorage from the effects of both weather and long shore drifts. Breakwaters reduce the intensity of wave action in inshore waters and thereby reduce coastal erosion or provide safe harbor for all types of marine craft.

The Long Beach breakwater was built as a part of the deep-water port project. The construction of the San Pedro and Middle Breakwaters started in 1899 and 1932, and completed in 1912 and 1942 respectively. The construction of the Long Beach Breakwater started in 1941, but was halted in 1943 due to WWII. Construction was resumed in 1946, and completed in 1949. The U.S. Navy moved in to the port of Long Beach in 1940 and used the breakwaters for military purposes.

The massive rocks that made up the 2.2-mile-long Long Beach breakwater were shipped from Catalina Island to create the World War II barrier that protected the Pacific Fleet.

Over the years, the Long Beach breakwater has been exposed to a number of large storms that have severely damaged the breakwater in several areas. The Army Corps of Engineers has been assigned the responsibility of maintaining the breakwater and repairing storm damage. Connolly-Pacific Co. was awarded a $5 million contract by the U.S. Army on Sept. 18, 2017. Repair work began on October 8, 2017.

Repairs on the Middle Breakwater, which was damaged by “heavy waves” hitting them during Hurricane Marie, are expected to be completed by late December 2017, barring unforeseen circumstances.

The contract authorized work to be done within 90 days. Repairs are being made to the 12 most severely damaged sections of the three breakwaters damaged by heavy seas from Hurricane Marie, according to the Army Corps.

Between 20,000 and 30,000 tons of rock acquired from Catalina Island’s Pebbly Beach quarry were expected to be used to fill gaps in areas most damaged by Hurricane Marie. Each rock weighs between 8 and 15 tons. While each breakwater was still functional after the hurricane, the functionality would decrease with each significant wave or storm event in the area.

According to the Army Corps, the Middle Breakwater is about 18,500 feet long and serves as a major structure that protects the Port of Long Beach. An estimated 1,550 feet of breakwater suffered major damage, with another 850 feet significantly damaged. About 1,725 feet of breakwater is moderately damaged.

Pro-Cast Products, Inc. made an introductory sales call on Connolly-Pacific to identify any potential, future opportunities. At that time, Connolly-Pacific was working in conjunction with the Army Corps of Engineers to design, build and install a series of concrete stairways placed at regular intervals along the entire breakwater. The intent of these stairways was to allow inspectors to safely access the breakwater to inspect the integrity of the structure.

Connolly-Pacific discussed this opportunity with the Pro-Cast’s sales rep and provided him with set of conceptual drawings. The design/engineering team at Pro-Cast studied the conceptual plans and contacted one of their partners (RediStair) to come up with a design that could be presented to CP and the Corps for review and approval. Eventually, the plans were approved, a PO was issued and production began on a single, test stairway. Once the test unit was delivered, CP installed it and approval for an additional 16 stairways was issued. Each stairway is positioned at approximately 1,000ft intervals the entire length of the breakwater providing safe and easy access for the inspection team.

Below is a short video on how these precast concrete stairways were easily installed at the breakwater.

This is yet another example of how the Pro-Cast Products’ sales/design/engineering team worked closely with the customer to develop a cost-effective solution that was delivered on time and within budget.

Author: Don Bailey, Sales Representative

by Jason

Fast Facts

Project Title: Runway 6L-24R Safety Area and Rehabilitation

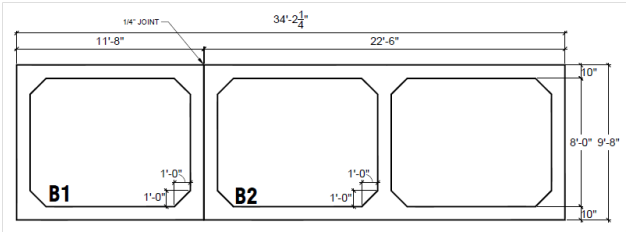

Precast Concrete Scope of Work: 10’x8’x8’L Singles and 10’x8’x4’L Doubles

Owner: Los Angeles World Airport

Year: 2015

Design Load: Aircraft Loading (Airbus A-380)

According to Los Angeles World Airports (LAWA), Los Angeles International Airport (LAX) is the 6th busiest airport in the world and 3rd busiest in the United States, serving 61 million passengers annually in 2012. The proposed Project is an integral part of the infrastructure and modernization program at LAX and Los Angeles World Airport’s (LAWA) commitment to maintain a safe and secure airport. As part of the proposed Runway 6L-24R Safety Area and Associated Improvements Project, Runway 6L-24R and service roads at LAX will be improved to enhance safety and maintain efficient operations.

As part of the construction of the proposed Runway Safety Area (RSA), a portion of the nearby Argo Ditch will be covered. In order to maintain an unobstructed, steady flow of water, a triple cell box culvert – which is a combination of a double and single 10’ inside width by 8’ inside height – will be constructed prior to backfill. The two different configurations of box culverts will be laid out side-by-side to form the required triple cell box culvert.

There was an additional challenge which is to design the precast concrete box culverts to handle the heaviest aircraft possible to land at the Los Angeles International Airport (LAX) which was modeled to be the Airbus A-380. With Pro-Cast Products extensive experience and highly knowledgeable design team, we were able to get the approval on the precast box culvert design that we confidently believe will safely handle the massive load.

To date, Pro-Cast Products had already successfully designed and produced triple and quad cell precast concrete box culverts. Pro-Cast Products is the first (and may be the only precaster up to this writing) to get a design approval from Caltrans to produce double and triple cell precast concrete box culverts for them. Noting that Caltrans’ Standard Plans D83a 2010 (and 2015) only list single cell precast concrete box culverts.

A precast concrete box culvert is a perfect solution to this type of application where quick installation is required in a tight construction timeframe. Pro-Cast Products had finished the box culvert production ahead of schedule and made sure they were cured and ready for delivery at the time the general contractor was ready for installation.

Backed by our strong engineering, production and quality control team, we are confident that we can design, manufacture and deliver every precast concrete product with pride. Pro-Cast Products is always ready to help you find precast concrete solutions to all your structural, civil and architectural construction needs. For more information and questions, please contact any of our sales staff at 909-446-9412 or send us an email to info@procast.us.

by pete

Our facility is located on 28 acres of land in Highland, CA. near the intersection of I-10 and I-210. We have direct, on site access to our concrete supply, thus improving our manufacturing process. We also have space set aside to store inventory of a variety of products for quick turnaround of orders.